A quiet option

When it comes to claims about acoustic levels from waste-water pipes it is sadly too easy for manufacturers to fool specifiers by using clever marketing tricks. according to Mike Rawlings, of Saint Gobain PAM UK. Even tests carried out to the appropriate standards do not go far enough in setting a level playing field.

There is an understandable drive to reduce costs on a building, but the informed specifier needs to ensure that they are comparing like for like. With waste-water drainage systems for instance, money saved on purchasing a cheaper plastic-based system will often be more than offset by the extra cost of installation and other materials needed to compensate for reduced performance.

This is clearly seen with meeting acoustic levels, where BS EN 14366:2004 sets out test criteria for measuring noise in waste-water systems. Its aim is to help specifiers make an informed choice.

The problem is that you may need to read the small print to find out what the test results show. Many manufacturers infer lower noise levels by including dB levels in a product’s brand name, but specifier beware because the level inferred in the title is measured at a much lower flow rate of water.

In addition, it is a growing opinion amongst consultants that BS EN 14366 does not go far enough when considering acoustic levels. Most noise within a pipe system comes from offsets in the stack and changes of directions through bends, yet the standard only measures water flowing through a vertical pipe.

There is also a question about what the optimum flowrate should be, the standard stipulates 4 l/s for a diameter of 100 mm.

So do the tests need to be more stringent to mimic real life situations? Or is it time for specifiers to determine what test criteria they want used?

|

| Most noise within a pipe system comes from offsets in the stack and changes of directions |

This is important, not just because it affects the final customer’s satisfaction with an installation (people do notice noisy pipes), but also because the UK code of practice BS8233 sets criteria for sound reduction in different types of buildings. These state that structure-borne noises from equipment behind the room must have a maximum noise level of 30 dB(A) in the main rooms of a residential property and a maximum level of 35 to 40 dB(A) in other rooms (such as kitchens or offices).

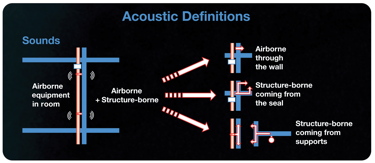

In practice the noise coming from pipe systems can come from two sources. One is the sound from water and air turbulence in the pipe, but the most noise will be generated from vibration of the pipe as a result of the water flow. This latter source can be transmitted through the wall by the pipe supports or the seals as the pipes pass through different floors.

For the specifier the challenge is to reduce any noise. Perhaps the simplest answer is to use the quietest material you can for the pipes. Independent studies continue to show that cast iron performs significantly better than even ‘acoustic plastic systems.

You can reduce noise through vibration transfer by using special pipe clips and clamps, enclosing the pipework within a mass of 15 kg/m2 or lagging the pipes with 25 mm of unfaced mineral fibre as described in Building Regulations Doc E.

There is also a question of how much can you actually reduce the noise using these solutions — and whether you will actually meet the required noise levels.

To answer these questions, TVVL, an independent consultancy, conducted 200 tests on waste-water systems and combinations of noise-reduction factors.

The tests compared a number of different materials. They included PVC, polypropylene, polyethylene and low-noise materials such as acoustic HDPE and cast iron. The tests all measured the noise from bare pipes without insulation and used a flow rate of 3l/s, which is comparable to a WC being flushed.

Noise levels ranged from 61.0 dB(A) down to 51.0 dB(A) for a vertical pipe and from 64.5 dB(A) to 50.5 dB(A) for a horizontal pipe. Measurements were taken at offset points and changes in direction. In all cases the best performing or quietest material was cast iron.

TVVL then extended the tests to include the effects of external acoustic insulation and other noise-reduction measures.

|

| Acoustic definitions for waste-water pipes explained. |

The laboratory concluded that if you used glass wool and an enclosure constructed from gypsum board, you could reduce the noise (or sound pressure level) by up to 30 dB(A) in walls. Using acoustic heavy sound proofing in the ceiling can reduce noise by up to 25 dB(A).

The report shows that pipe systems can get down to the acoustic levels required for most buildings, but for materials other than cast iron require significant insulation to do so.

The best advice is to ask to see independently verified test results. At the moment the best test is to BS EN 14366:2004, but you need to ensure that you are looking at comparable flowrates and the correct bracket solutions.

I would argue that the easiest and possibly most cost-effective way to comply with the standards is to choose the quietest pipe material available — and that remains cast iron.

Mike Rawlings is marketing manager with Saint Gobain PAM UK.